We help the world growing since 2013

DSP ENGINEERING introuduces the most sturdy, heavy duty SIGMA MIXER for trouble free long term operation for various application like mixing, kneading, grinding, dispersion, drying etc.

Our SIGMA MIXERS have application to process Viscous to highly Viscous material in various industries viz. Adhesives, Broke lining, Chemical, Confectionery, Carbon Black, Ceramic, Dyes & Pigments, Food Products, Fibre Glass, Grease, Lead Storage Battery, Megnetic Tape Coatings, Paint, Polymers Plastic, Putties, Plastic, Pharmaceuticals, Printing ink, Resin, Rubber, Soap & Detergent etc.

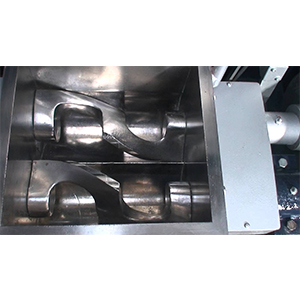

SIGMA MIXER consist of "W" shaped container made of either Mild Steel or Stainless Steel 304 or 316 with jacket of Carbon Steel covering two side for heating or cooling application & dust free cover to get Vacuum if desired or normal cover.

The mixing elements (Blades) are of Sigma type Steel casted and duly finished two in number which contra rotate inward fitted at close or specified clearance with the container to give thorough and uniform mixing. There is a Gland pusher of Gun Metal Bush which ensure minimal friction and extend the life of mixing elements (Blades) Shaft.

The Drive Consists of Motor of type TEFC Or Flameproof of Specified HP.1 440 RPM, Reduction Gear Box Of Reputed Make having suitable size and ratio, Spur Gears, are also provided of adequate size and having machine cut teeth, between the front and rear blade complete with guard suitable for grease lubrication.

The complete Mixer is Mounted on Steel Fabricated stand of suitable strength to withstand the vibration and give noise free performance.

SIGMA MIXER as the name suggests contains mixing element (Blades) of Sigma type two in number which contrarotates inward to achieve end to end circulation & thorough & uniform mixing at close or specified clearance with the container. The mixed product can be easily discharged by tilting the container with the help of screw with motorised system(motor and gearbox), by hand lever system of gears manually operated or by hydraulic & power pack system.

| Adhesives | Food and confectionery products | Pencil erasers |

| Biscuit doughs | Gaskets and Gland Packings | Pharmaceuticals |

| Butyl rubber | Grinding wheel preparations | Plastics |

| Carbon pastes | Hot-Melts | Putties |

| Ceramics | Inks and pigment products | Refractories |

| Chemicals | Marzipan | Solid propellants |

| Chewing gum | Mastics | Sugar pastes |

| Crayon and pencil lead | Metal powders | Sealing compounds |

| Explosives | Moulding preparations | Silicone rubber |

| Fiberglass resin doughs | Soaps and detergents | Viscous rubber solutions |

| MODEL | CAPACITY - LTRS. | MOTOR HP | |

|---|---|---|---|

| WORKING | BRIM | ||

| DSP-25 | 25 | 40 | 3 |

| DSP-50 | 50 | 80 | 5 |

| DSP-100 | 100 | 150 | 7.5 / 10 |

| DSP-150 DSP-200 |

150 200 |

200 300 |

12.5 15 |

| DSP-300 DSP-400 |

300 400 |

400 550 |

25 30 |

| DSP-500 DSP-600 |

500 600 |

650 800 |

30 40 |

| DSP-1000 DSP-1200 |

1000 1200 |

1500 1800 |

50 50 |

| DSP-1500 | 1500 | 2000 | 60 |

| DSP-2000 | 2000 | 2500 | 75 |

| Double row series, angular contact metric, ball bearing | |||||||

|---|---|---|---|---|---|---|---|

| LOAD RATING - KN | |||||||

| MODEL | Bearning No | ID | OD | Width | Dynamic - c | Static - cd | Speed Limit RPM grease |

| 25 Ltrs DSP 25 |

3209 | 45 | 85 | 30.2 | 40 | 40 | 5000 |

| 50 Ltrs DSP 50 |

3210 | 50 | 90 | 30.2 | 45 | 45 | 4800 |

| 100 Ltrs DSP 100 |

3211 | 55 | 100 | 33.3 | 49 | 52 | 4300 |

| 150 Ltrs 200 Ltrs DSP - 150/200 |

3213 | 65 | 120 | 38.1 | 67 | 73.5 | 3600 |

| 300 Ltrs 400 Ltrs DSP - 300/400 |

3215 | 75 | 130 | 41.3 | 78 | 86.5 | 3200 |

| 500 Ltrs 600 Ltrs DSP - 500/600 |

3217 | 85 | 150 | 49.2 | 102 | 118 | 2800 |

| 1000 Ltrs 1200 Ltrs DSP - 1000/1200 |

3218 | 90 | 160 | 52.4 | 112 | 132 | 2600 |

| 1500 Ltrs DSP - 1500 |

22220 | 100 | 180 | 46 | 275 | 240 | 1900 |

| 2000 Ltrs DSP - 2000 |

22222 | 110 | 200 | 53 | 355 | 315 | 1700 |